our mission

Enable today’s manufacturers to increase the capabilities of their turning centers through the implementation of innovative solutions at competitive prices.

MD Tooling was established in 2003, leveraging years of Machine Tool experience and the desire to provide exceptional support and service to customers with tooling needs. MD Tooling began a partnership with M.T. Marchetti, a world leader in innovative design and production of driven and static tools for CNC turning centers. This combination allows MD Tooling to provide the very best to their customers.

MD Tooling – your partner for tooling solutions

-

Machine tool accessory providers face a lot of choices. What tools to offer, what kind of support to provide, what level of service to supply as well as what level of commitment to make to their customers.

At MD Tooling:

We choose to provide solutions consisting of high accuracy, quality products that are designed to help our customers maximize their productivity.

We choose to develop new and creative tool holding solutions to maximize the productivity of today’s machine tools.

We choose to support our customers in their quest to remain aggressive and competitive in a worldwide market.

We choose to support our products through a knowledgeable staff that provides fast, friendly, reliable service.

We choose to create the ultimate customer experience backed by guaranteed satisfaction.

-

It takes more than just high quality products to solve the problems faced by today’s manufacturers. It also takes a commitment to provide the highest level of support and service. At MD Tooling this is not something we just think about, it is something we do.

Stock and Replenishment – MD Tooling maintains an extensive inventory of the tools you need to keep you up and running. 93% of all orders are shipped same day.

Tool Loaner Program – Leading the way in customer service, MD Tooling’s loaner program keeps you up and running.

Technical Support – Our application engineers with over 35 years of CNC experience are available to help answer any question you may have about our tooling or any other CNC related issue. We can tool up your job from blue print and can even help with part programming if needed.

In-house Service and Warranty Work – MD Tooling will evaluate your repair needs to determine the service level, preforming all level 1 repairs at our Michigan Service Center. Those requiring factory re-certification are shipped back to Italy. MD Tooling will repair any defective tool holders for a period of 2 years from the date of purchase.

It is very easy to see why so many customers have declared MD Tooling – The Right Choice!

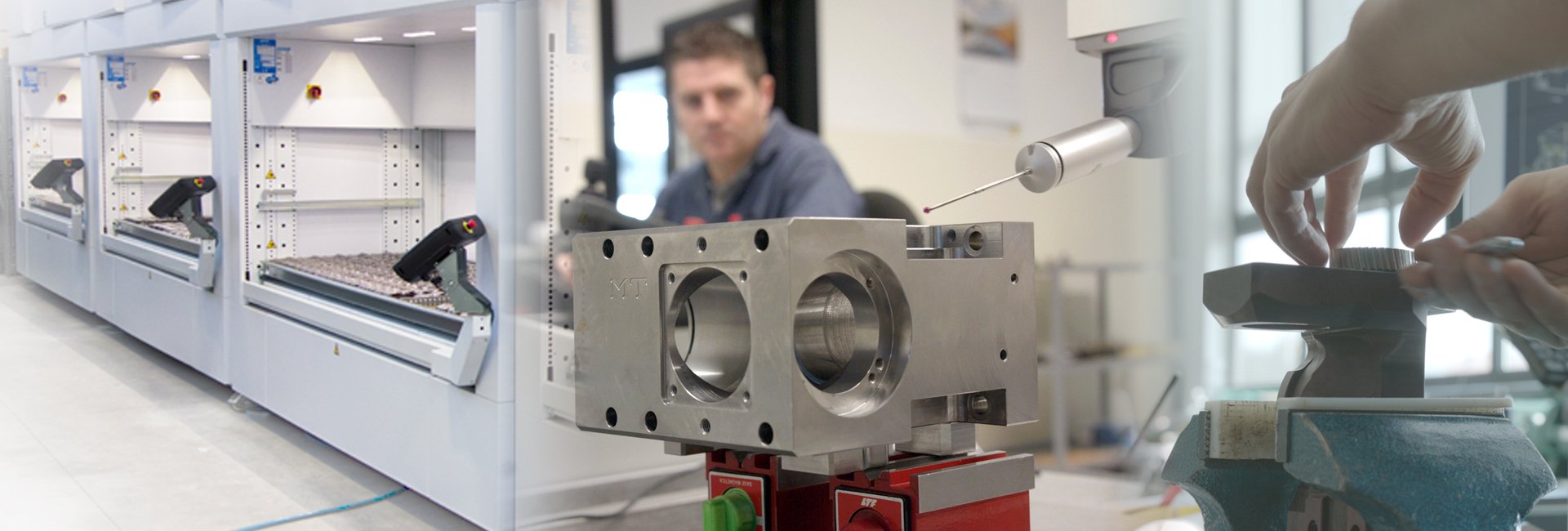

M.T. S.r.l (Marchetti) is a family owned business founded in 1972 and headquartered in Rimini, Italy. Marchetti is a world leader of innovative design and production of driven and static tool holders for CNC turning centers.

Originally a specialist contract manufacture of finished mechanical parts, Marchetti started producing driven and static tooling for CNC lathes in the 1990s. In addition to its extensive tooling ranges Marchetti also manufactures high precision special purpose driven tooling made to customer specifications.

Exclusive North American Supplier for M.T. Marchetti

-

With over 2500 standard products, the company is able to meet the most demanding needs of its customers, offering customized solutions on request.

Respected for products like multi-spindle tools, Y-axis live and static tools, multi-position static tool holders, sliding steady-rests and MTSK quick change systems.

Tool holders with as many as 8 live ER25 spindles in one tool means you can have 4 tools facing the main spindle and 4 tools facing the sub spindle in one turret station.

Y axis static holders save time and money with a holder that will hold 4 static tools in one turret station. You can rough turn and then finish turn on the main and the sub spindles without ever indexing the turret.

Fewer turret indexes save cycle time, as well as wear and tear on your turret.

Geared up holders to 60,000 RPM and 1,000 PSI coolant through.

-

All of the tooling available have been designed to give years of service in the most demanding applications. It is not uncommon for MD Tooling’s tool holders to last four or five years. Given the longevity of our tool holders we are able to back them with a 2-year factory warranty. MD Tooling will repair or replace any defective tool holders for a period of 2 years from the date of purchase.

-

M.T. Marchetti follows the stringent quality and inspection procedures which include:

Verification of material type and traceability.

Heat treatment certification.

100% inspection of critical components.

Ceramic coating of all central shafts for extended life.

Utilization of seals to withstand 70 bar pressure on coolant through driven tools.

Finite measurement of roundness and concentricity of all central shafts guaranteeing a 4 micron maximum run-out of the finished tool.

Integration of super precision bearings for use on all driven tooling.

Final inspection and test of every driven and static tool.

Individual serial numbers / code references laser etched on the side of every driven and static tool to identify the manufacturing and dispatch date.

-

Innovative tool design is a key reason we are the fastest growing manufacturer of live tooling. The Research and Development Department at M.T. Marchetti are constantly evaluating the processes of today’s manufacturers to develop new and innovative solutions. Recent developments include an MTSK Quick Change Removal System which has a quick change clamping nut so the modular tool adapters can be easily ejected.

Products such as our adjustable angle gear cutting or hobbing holder for your turning center are truly on the forefront of turning technology. The Gear Hobber allows you to hob spur gears, bevel gears, helical gears and spline shafts in your turning center along with your turning process. As innovative thinkers, we see no need to stop at just the standard radial and axial line up of tool holders. We embrace the innovative process that has made US manufacturing a world leader and continue to develop unique live tooling to help our customers save time and money.

our customers

Amphenol Aerospace

Analytical Scientific

Bimba Manufacturing

Brinkman Precision

Bush Hog

Cascade Precision

Dana Corporation

Eaton Aerospace

Everite Machine Products

Ford

General Manufacturing

Greenlee Textron

Harford Machine Shop

Hydra-Electric Company

Integra Medical

ITT Aerospace

JET Aerospace

Joy Mining Company

Kenlee Precision

Maehr Industries

Magnetic Component Engineering

Metaldyne

Moog Aerospace

Northstar Aerospace Incorporated

Oshkosh Marine

Parker Hannifin

Nichols Aircraft Division

Finite Filter Division

Paul Precision Machine

Precor USA

Pennsylvania Rail Car Company

Rockmore International Inc.

Roush & Yates Racing

Sig Sauer

Smith & Nephew

Snap-On Tools

Spirit Aerospace Components

Stryker Medical

Stryker Orthopedics

Synthes USA

Thompson Center Arms

Timken

Vickers Engineering

Wright Medical Technology