Allows the machining of external teeth, with straight and helical teeth, directly on the lathe.

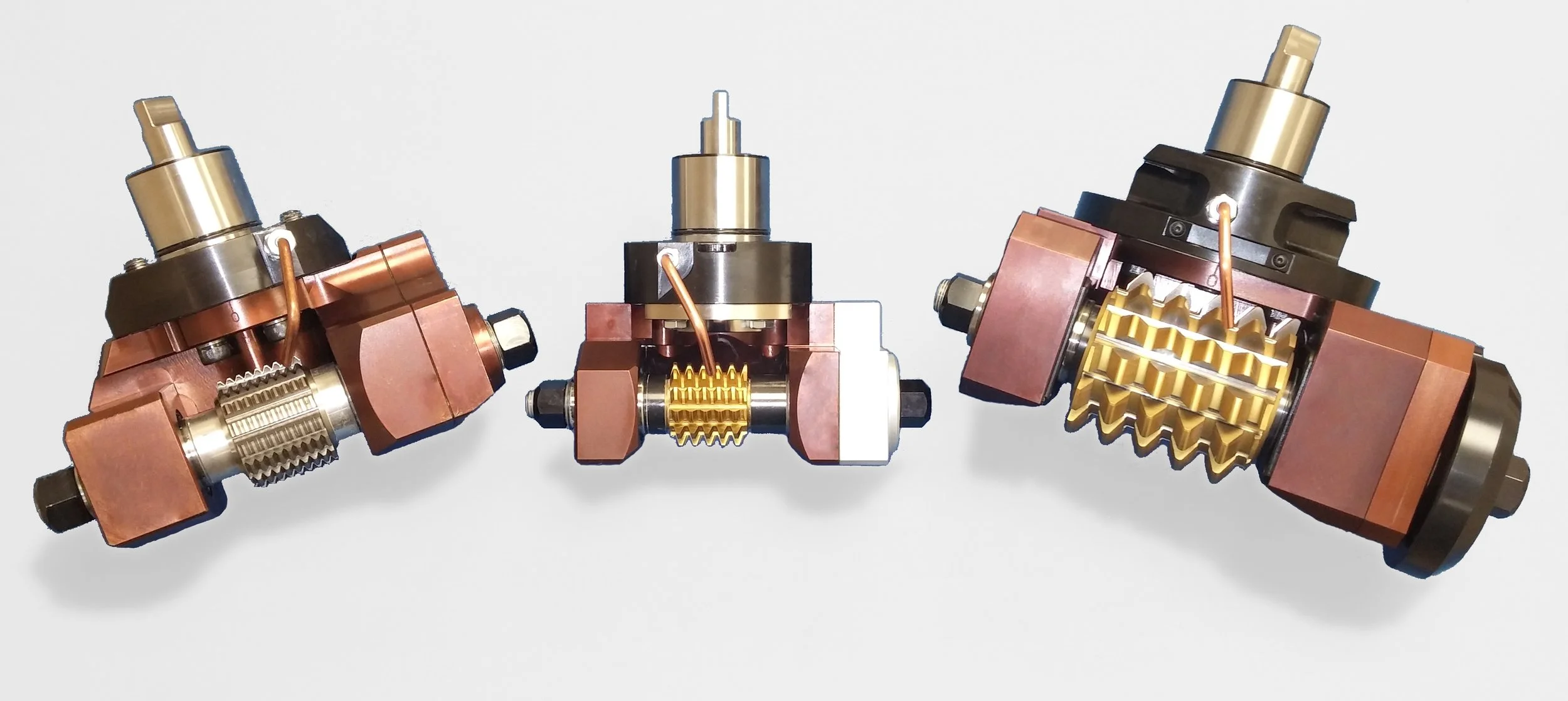

Driven Gear Hobber

With our driven gear hobber you can perform the machining of gears directly on the turret lathe, avoiding the dead times due to the set-up on two different machines (lathe and gear-hobbing).

The machining of cylindrical gears with straight or helical teeth, as well as conical gears with straight teeth, is possible.

M.T. driven gear hobber is available with reduction ratio 1:1 or 2:1, allowing the machining of different types of gears also with limited power available on the driven tool turret.

M.T.'s driven gear hobber can be angularly adjusted, in order to machine helical gears. The stability of our design grants very high finishing grades, together with high cutting parameters. The gear cutter can be easily changed, granting reduced set-up times.

Product Features

Our driven gear hobber is available for many different machine types and in five sizes:

Light: suitable for gear cutters up to diameter 40 mm, length 43 mm

Standard: suitable for gear cutters up to diameter 50 mm, length 50 mm

Medium: suitable for gear cutters up to diameter 80 mm, length 80 mm

Strong: suitable for gear cutters up to diameter 80 mm, length 80 mm

Heavy Duty: suitable for gear cutters up to diameter 100 mm, length 100 mm

A very small size unit, dedicated to light gear cutting on swiss type lathe, is also available. With our heavy duty driven gear hobber, together with the proper machine, the machining of gears up to module 4 is possible.

Our Technical Department is ready to assist you for the selection of the suitable toolholder and related machine parameter according to you specific application.